A POWER CABLE is explicitly intended for sending power. It even does the trick the motivation behind dissemination. It involves no less than one freely safeguarded electrical transport, ordinarily held together with an overall sheath. The item is used for transmission and allotment of electrical power.

The POWER CABLES is supported by electrical energy may be presented as enduring wiring inside structures, made in the progress, and run vertical or revealed. Versatile power joins are used for advantageous devices, portable instruments, and hardware.

These are arranged and created by voltage, current to be conveyed, working most outrageous temperature, and justification behind applications needed by the client.

For mining, we give extra mechanical fortitude to POWER CABLES with twofold building up. For the clients of wind POWER CABLES all around, require versatile and UV protected interface with the mechanical outrageous sheath so we plan as indicated by their essential. Our fine items like power links are dealt with by specialists.

The underground connections partake in a couple of advantages, for instance, these are less committed to hurt through storms, lightning, low help cost, a lower chance of issues, the much unobtrusive voltage drop, and a predominant outward show.

Out of all brands Techno flex Cable has guaranteed a specialty in the electrical transport industry. A wide item portfolio will undoubtedly keep their in front of contenders.

Techno Flex Cables are one of the best Power Cables manufacturer, Power Cables exporter, Power Cables supplier in Mumbai, India. We are serve in all Asian, Gulf, and African countries efficiently. If you want this product please quote Now!

Plain bright annealed copper / alluminium, solid / stranded conductor confirming to IS: 8130: 1984.

Type A, B, & C (HR) grade according to IS: 5831 : 1984 amended up dated.

Inner sheathing shall done by extrusion or by PVC tape binding that laid up cores shall not loose and prevent to water entering.

Gl armour wire / strip provides not only mechanical support but also earthing. The material use an according to IS : 3975 : 1974 amended up dated.

Extruded STI / ST2(HR, FRLS, Halogenfree FRLS) type PVC is used according to IS : 5831: 1984.

In Thermal Power Station; Petrochemical Refineries; Steel & Cement Plant; Distribution System; Digital Control and Monitoring & Information systems; Air Ports; Building Towers; etc.

Techno Flex manufacture heavy duty Power Cable comprising of cores Single / Two / Three / Three & Half / Four Of Alluminium Conductor, PVC Insulated cores laid up, PVC Inner Sheathed OR PVC tape binding, GI wire / Strip Armoured & overall PVC sheathed cable confirming to IS : 1554 : Part-I.

Basic assumption for Current ratings

(1) Max. Conductor Temp. : 70°C

(2) Thermal resistivity soil : 150°C CM/W

(3) Thermal resistivity of rvc : 650°C CM/W

(4) Ground temperature : 30°C

(5) Amb. air temperature : 40°C

(6) Depth of laying : 75 cm (Highest pt. of cable laid)

1. Rating Factor for depth of laying Twin & Multicore Cables

| Depth Of laying cm | upto 25mm2 | Above 25mm2 & 300mm2 | Above & 300mm2 | Multicore |

|---|---|---|---|---|

| 75 | 1 | 1 | 1 | 1 |

| 90 | 0.99 | 0.98 | 0.97 | 0.99 |

| 105 | 0.98 | 0.97 | 0.96 | 0.98 |

| 120 | 0.97 | 0.96 | 0.95 | 0.97 |

| 150 | 0.96 | 0.94 | 0.92 | 0.96 |

| 180 or more | 0.95 | 0.93 | 0.91 | 0.95 |

2. Rating Factor for the Single Core Cables (AC) in the formation in Air Applied to the corresponding ratings for trefoil groups in air.

| Nominal Area Of Conductor mm2 | Rating Factor |

|---|---|

| Upto & Including 185 | 1.07 |

| 240 | 1.10 |

| 300 | 1.08 |

| 400 | 1.04 |

| 500 | 1.00 |

| 630 | 1.00 |

3. Rating Factor for variation in underground temperature for cables laid direct in ground & laid in duct.

| Ground Temperature °C | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

|---|---|---|---|---|---|---|---|

| Rating Temperature | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 | 1.17 |

4. Rating Factor for variation in underground temperature for cables laid direct in ground & laid in duct.

| Ground Temperature °C | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

|---|---|---|---|---|---|---|---|

| Rating Temperature | 1.33 | 1.25 | 1.16 | 1.09 | 1.0 | 0.90 | 0.83 |

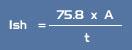

Short Circuit Rating Of Alluminium Conductor Cable :

Techno Flex cables manufacturing method based on quality assurance plan & use of high standard raw material, therefore it withstand high Magnitude of short circuit rating. It is calculated as under:

where

Ish --> short circuit ratings in r.m.s. amp.

t --> duration of short circuit in seconds

A --> Area of conductor in sq.mm

Tabulated The Constant For Different Duration Of Short Circuits :

| Duration of Short Circuit in sec. | 1 Cycle = 0.02 sec | 2 Cycle = 0.04 sec | 5 Cycle = 0.1 sec | 10 Cycle = 0.2 sec | 25 Cycle = 0.5 sec | 50 Cycle = 1.0 sec | 2 sec | 3 sec | 4 sec | 5 sec |

|---|---|---|---|---|---|---|---|---|---|---|

| Short Circuit constant Per unit area | 536 | 378 | 239 | 169 | 107 | 75.7 | 53.0 | 43.6 | 37.8 | 34 |

Example: Short Circuit rating of 70 sq.mm area of conductor with short duration 0.5 sec = 70 x 107 = 7490A

Recommendation For Installation:

Cables are the most important asset of any organization. Any damage to it will result in break down of the complete plant & machinery, hence proper attention should be paid while handling and laying them. So for its silent features which should be kept in view during installation as under:-